-

Notifications

You must be signed in to change notification settings - Fork 2.2k

Open

Labels

Description

Version

2.3.0+linux64+gtk3

Operating system type + version

Debian unstable

3D printer brand / version + firmware version (if known)

very modified cr10 S4

Behavior

- First: thanks a lot for PrusaSlicer and the new ironing feature! Works very well so far except for this case.

- I'm printing with the

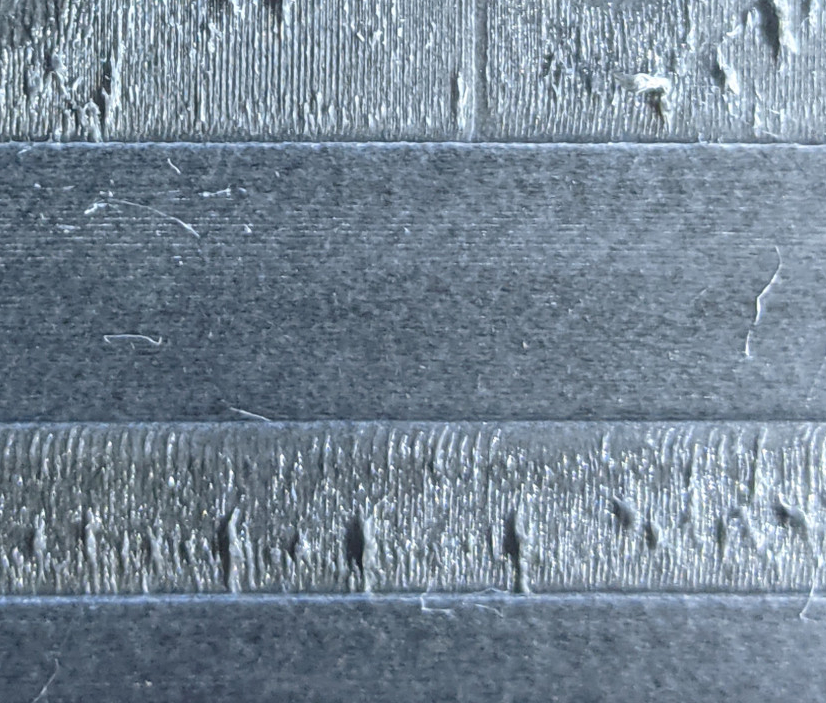

extrudr greenTec pro carbonfilament, which contains carbon fibers. 0.5mm nozzle minimum, I'm using a 0.6mm e3d hardened steel nozzle.

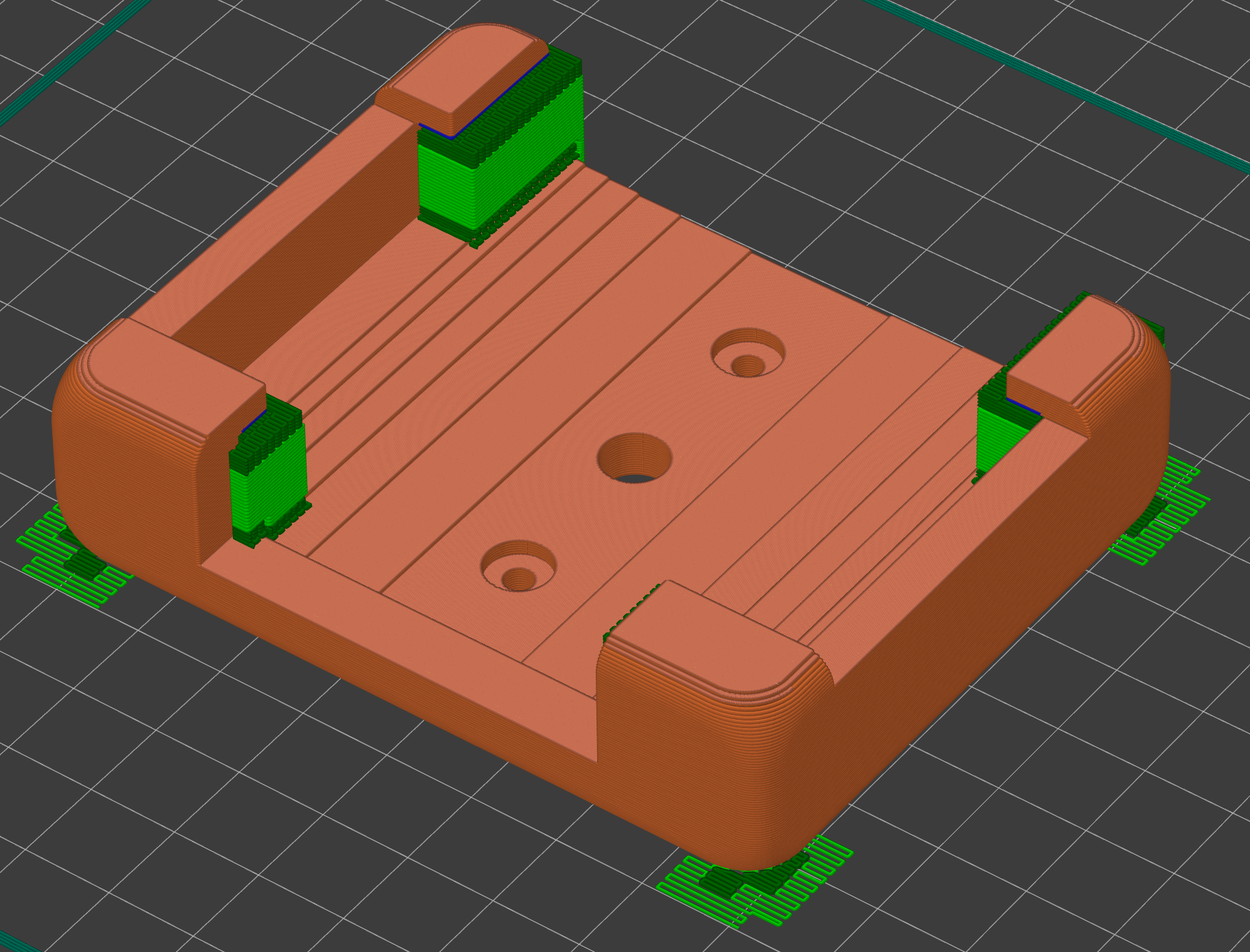

- Ironing the 4 top areas, where the nozzle is moving out of the printed area into the free space while ironing worked very well. Also all the areas in the middle where the nozzle moved a long straight distance (from left to right in the image below).

- The problem is in the small striped where (why??) ironing was done in very short movements (up and down in the image). Here the nozzle pulled carbon fibers out of the printed area due to the movement (I guess). It was not hard to remove them with a fine sand paper, resulting in an almost flat surface, but more sanding would be needed to have a finish as nice as the areas that were ironed from left to the right. I think especially for ironing moving the longest distance first would make sense, as you want to have a very equal look, with less unnecessary movement.

- I'd assume that this issue is mainly visible with filaments that contain some kind of fibres, like carbon or wood.

Is this a new feature request? - Maybe. Might make sense to make the behaviour configurable, but I think the default behaviour should be to choose the longest possible path first.

Project File (.3MF) where problem occurs

https://shell.bzed.at/~bzed/.publish/2021-01-15-NzeKEbsHVj0/pixel5.3mf