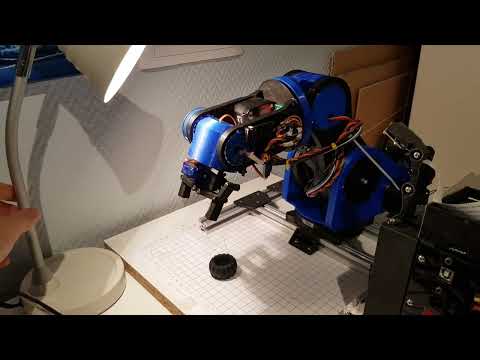

A 6‑DOF robot arm that can pick up stuff. Most parts are 3D‑printed, an Arduino Mega + RAMPS 1.4 drives the motors, and a Raspberry Pi with a Pi Camera is used for the object detection.

- 6‑joint arm (6‑DOF) that can grab small objects

- Mostly 3D‑printed parts

- Steppers for the big joints, a large servo for one joint, and a tiny servo for the gripper

- Limit switches on the stepper joints for homing

- Raspberry Pi + Pi Camera does the vision, talks to the Arduino over serial

- Forward and inverse kinematics baked in

- Pick‑and‑place demos included

Mechanics

- Nearly everything is 3D‑printed.

- DIY ball bearings: BB pellets inside printed races (cheap and good enough).

Motors

- Mix of NEMA‑17 steppers.

- One 28‑BYJ48 unipolar stepper for a light joint.

- One larger servo for a joint.

- One micro servo for the gripper.

Control + Sensors

- Arduino Mega + RAMPS 1.4 for motors and limit switches.

- Raspberry Pi + Pi Camera for object detection.

- Arduino firmware handles steppers/servos and homing.

- Raspberry Pi runs the vision code (OpenCV /

cv2) and sends target positions to the Arduino. - You can pick a region in the camera image, the code deskews it, and maps pixels to the arm’s XY plane with a quick calibration.

The forward and inverse kinematics are adapted from this project (tuned for this arm’s links and joint directions):

https://github.com/glumb/robot-gui/blob/master/js/Kinematics.js

- Uses OpenCV to find objects in the selected area.

- Right now it doesn’t consider object width or in‑plane rotation (that’s on the roadmap).

Video demo — Click the image to watch on YouTube

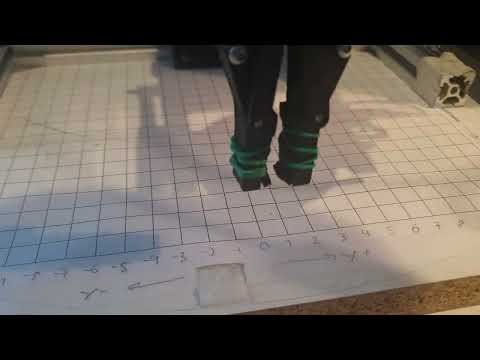

- In the UI, pick four points to mark the area where the arm should look.

- The code deskews that patch to handle camera angle.

- Give the system two known points (with their arm‑frame coordinates, arm center is

(0, 0)). From that, it scales/shifts so any pixel becomes an XY in the arm frame.

Mapping test video — Click the image to watch on YouTube

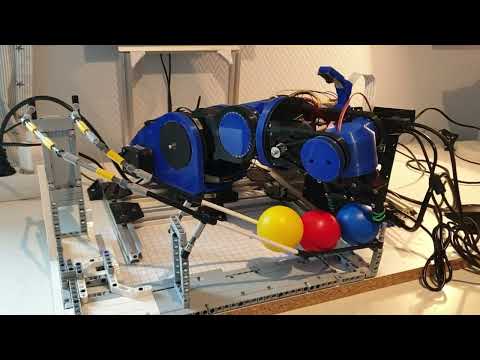

A small example where the arm picks up a ball and drops it somewhere else.

Pick & place video — Click the image to watch on YouTube